HOME

> PRODUCTS > Atmospheric (atmospheric) plasma > Atmospheric (atmospheric) wide range plasma equipment

Atmospheric pressure (atmospheric) wide plasma equipment

Product advantages:

1. Better treatment effect: The surface value of discharge is increased to 50mm, which can improve the cleaning effect by 3~5 times compared with ordinary atmospheric pressure plasma cleaners.

2. Faster processing speed: up to 8M/min.

3. Lower process temperature: the lowest process temperature is ≤40oC, which effectively protects the product and does not cause thermal damage.

4. More stable process control: The plasma discharge is more stable, does not generate arcs, and does not generate electrical damage.

5. Lower cost of use: Nitrogen (N?) and compressed air (CDA) are used as process gases, nitrogen generators are available, and maintenance costs are low.

6. Less dust generation: unique electrode structure and processing method minimizes the generation of dust (Particle)

Online query

1. Better treatment effect: The surface value of discharge is increased to 50mm, which can improve the cleaning effect by 3~5 times compared with ordinary atmospheric pressure plasma cleaners.

2. Faster processing speed: up to 8M/min.

3. Lower process temperature: the lowest process temperature is ≤40oC, which effectively protects the product and does not cause thermal damage.

4. More stable process control: The plasma discharge is more stable, does not generate arcs, and does not generate electrical damage.

5. Lower cost of use: Nitrogen (N?) and compressed air (CDA) are used as process gases, nitrogen generators are available, and maintenance costs are low.

6. Less dust generation: unique electrode structure and processing method minimizes the generation of dust (Particle)

| Number | Content | Specification Parameters |

|---|---|---|

| 1 | Type | Plasma Cleaning |

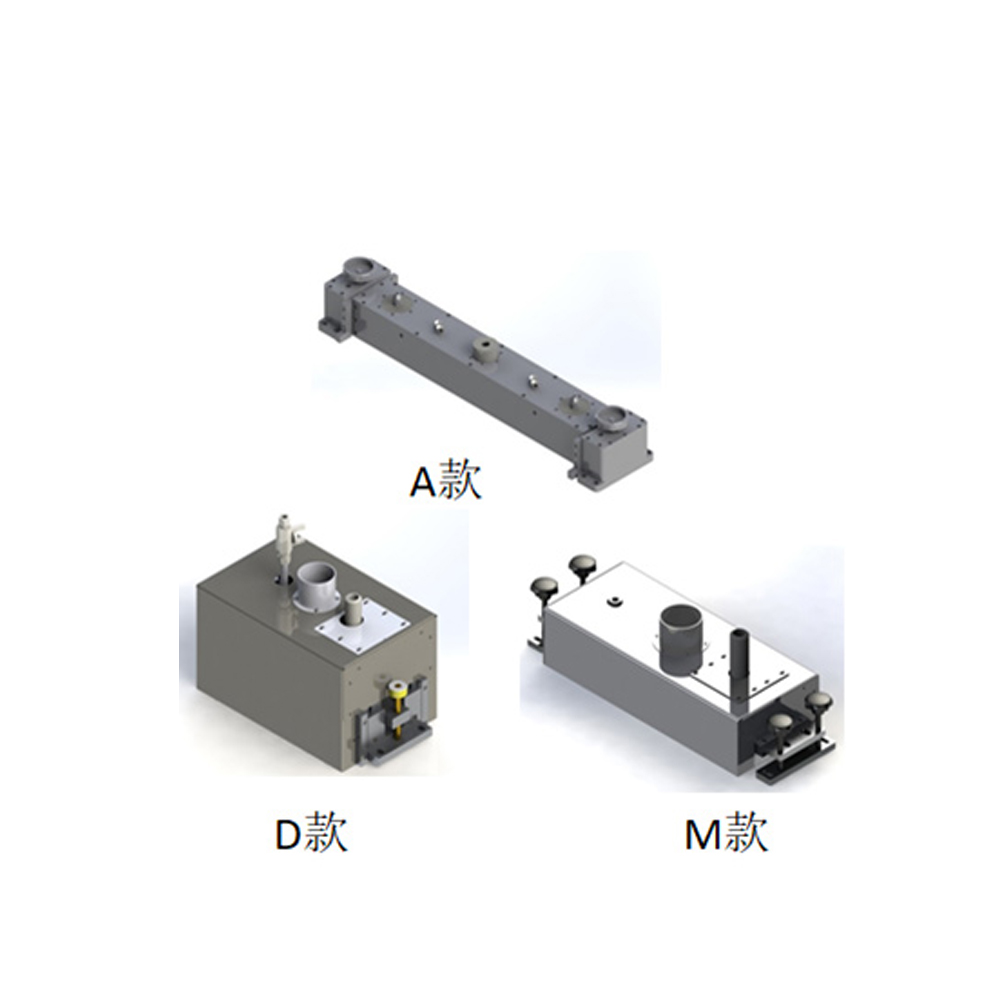

| 2 | Model | Type A/M/D: 100~3270mm (handling width) |

| 3 | Constitute | Plasma power supply, UT gas control unit, plasma electrode unit |

| 4 | Process gas | N2 + CDA |

| 5 | Processing spacing | 3~12mm |

| 6 | Processing temperature | ≤50oC |

| 7 | Drop angle | ≤10°(100mm/s) |

| Product advantages: 1. Better treatment effect: The surface value of discharge is increased to 50mm, which can improve the cleaning effect by 3~5 times compared with ordinary atmospheric pressure plasma cleaners. 2. Faster processing speed: up to 8M/min. 3. Lower process temperature: the lowest process temperature is ≤40oC, which effectively protects the product and does not cause thermal damage. 4. More stable process control: The plasma discharge is more stable, does not generate arcs, and does not generate electrical damage. 5. Lower cost of use: Nitrogen (N?) and compressed air (CDA) are used as process gases, nitrogen generators are available, and maintenance costs are low. 6. Less generation of dust: Unique electrode structure and processing method minimizes particle generation Product application: 1. Widely used in LCD (2G~11.5G) and OLED production processes. 2. Widely used in TP (touch screen) production process. 3. AF coating (anti-fingerprint), AS coating (anti-scratch), AG coating (anti-glare), AR coating (anti-reflection) pre-treatment. 4. The pre-treatment of the full bonding of the display screen and the pre-treatment of the ACF pressing of the display screen. 5. Metal film (Cu, Al, etc.), non-metal film (PET, PI, etc.) coil coating, surface treatment before bonding. |

||

Related Products

Low temperature plasma direct spray gun (AJP-D series)

Low temperature plasma rotary spray gun (AJP-R series)

Atmospheric Rotating Spray Gun (AK1000-D Series)

Atmospheric pressure jet low-temperature plasma direct spray gun (PSM-300B series)

Atmospheric pressure wide range plasma equipment AP300-M

Low temperature plasma quasi-glow discharge surface treatment module

- 在線咨詢

- 微信咨詢

微信掃碼咨詢

- Tel

- Phone0755-81452366

- Tel13510501616

- Top